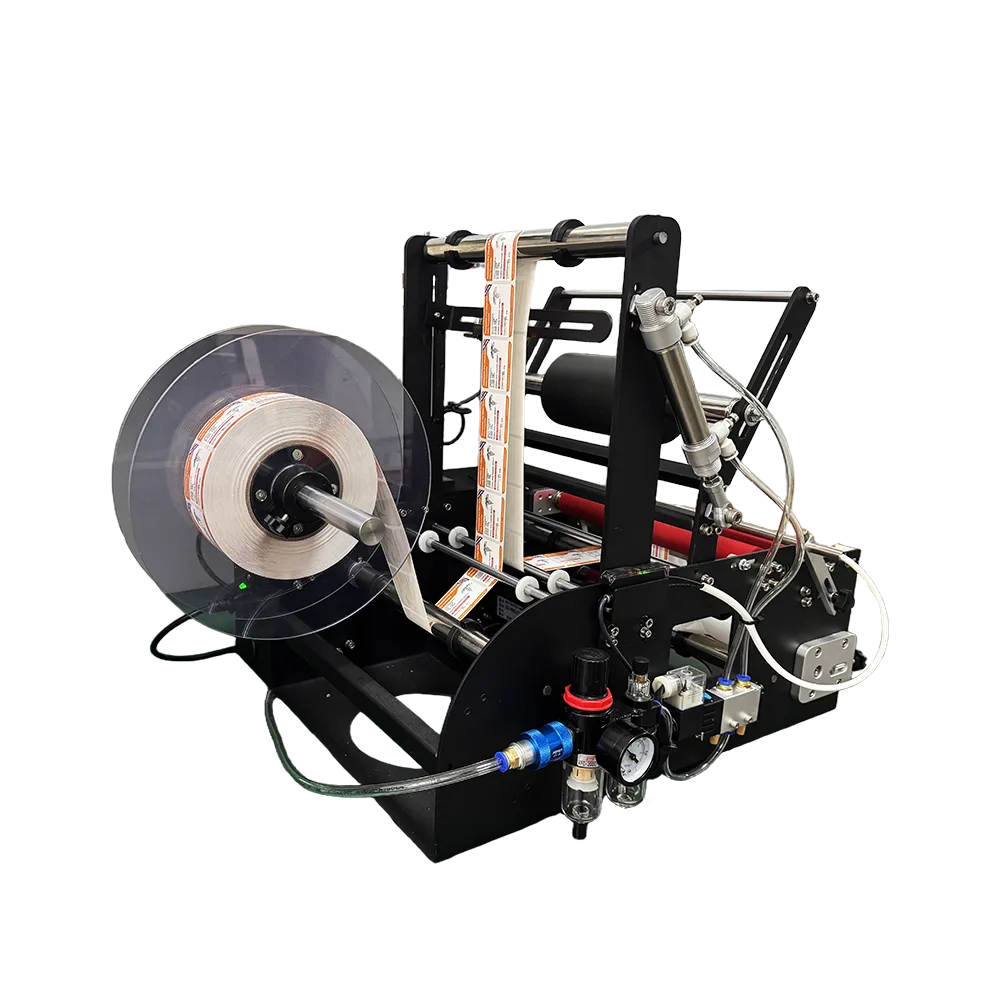

Semi Automatic Round Bottle Labeling Machine

Efficiency meets precision with a semi automatic bottle labeling machine designed for small-scale factories. A well-built semi automatic round bottle labeling machine enhances productivity, ensuring consistent label application with minimal labor.

Table of Contents

Introduction to Semi-Automatic Round Bottle Labeling Machines

Businesses investing in a high-quality semi automatic bottle labeler gain a competitive advantage through streamlined operations. Featuring adjustable settings, these machines accommodate various bottle sizes and label materials, making them indispensable for diverse industries. With user-friendly controls and durable construction, a bottle labeling machine improves workflow without requiring extensive training. Manufacturers seeking a cost-effective solution for labeling round bottles will find these machines an invaluable asset.

Key Features and Operational Benefits

Engineered for efficiency, a semi automatic bottle labeling machine combines speed, accuracy, and adaptability. High-precision sensors ensure flawless label placement, reducing material waste and increasing production quality. The semi automatic round bottle labeling machine allows for quick label changes, accommodating different product lines with ease. Operators benefit from an intuitive interface, making machine operation simple yet effective. Compact design saves space while maintaining high output rates. Durability and reliability ensure long-term performance with minimal maintenance. Businesses integrating a semi automatic bottle labeler can expect reduced labor costs and enhanced production efficiency, making their investment worthwhile.

Technical Specifications and Performance Metrics

Understanding technical specifications helps buyers make informed decisions when selecting a semi automatic bottle labeling machine. Standard features include adjustable label positioning, high-speed application, and compatibility with various bottle diameters. A semi automatic round bottle labeling machine typically operates at speeds ranging from 15 to 30 bottles per minute, depending on bottle and label size. Precision mechanisms ensure labels are applied without wrinkles or misalignment. A semi automatic bottle labeler supports different label materials, including paper, plastic, and film. Low maintenance requirements and durable construction contribute to the long service life of these machines, offering a reliable labeling solution for small-scale manufacturers.

Enhancing Production Efficiency in Small Factories

For small-scale manufacturers, automation is key to boosting efficiency without excessive costs. A semi automatic bottle labeling machine accelerates labeling speed while maintaining high precision. Compared to manual labeling, a semi automatic round bottle labeling machine drastically reduces errors and inconsistencies, improving product presentation. The semi automatic bottle labeler integrates seamlessly into existing workflows, allowing businesses to scale operations without significant infrastructure changes. Reduced reliance on manual labor lowers operational costs while ensuring a consistent production rate. Investing in a bottle labeling machine streamlines production, enabling businesses to meet higher demand with improved efficiency.

Customization Options for Diverse Labeling Needs

Flexibility is crucial in the labeling industry, and a semi automatic bottle labeling machine offers extensive customization options. Adjustable rollers and label sensors accommodate bottles of varying shapes and sizes. A semi automatic round bottle labeling machine can handle labels with different adhesives and materials, ensuring compatibility with specific branding needs. The semi automatic bottle labeler may include programmable settings for label placement, speed adjustments, and batch numbering. Modular components allow for further customization, ensuring the bottle labeling machine meets specific production requirements. These adaptable features make it a versatile solution for businesses with diverse labeling needs.

Integration with Existing Manufacturing Systems

Seamless integration enhances production efficiency, and a semi automatic bottle labeling machine fits effortlessly into existing workflows. Designed for plug-and-play operation, a semi automatic round bottle labeling machine requires minimal modifications for deployment. Businesses upgrading from manual labeling find the transition smooth and highly beneficial. A semi automatic bottle labeler operates independently or alongside filling and capping machines, improving end-to-end production speed. Connectivity options enable data tracking for improved quality control. Manufacturers leveraging a bottle labeling machine benefit from enhanced productivity, ensuring a steady supply of labeled products to meet market demands.

Maintenance, Safety, and Durability Considerations

Longevity and safety are essential factors when investing in a semi automatic bottle labeling machine. Regular maintenance ensures continued performance, with routine cleaning and lubrication preventing unnecessary wear. A semi automatic round bottle labeling machine includes safety mechanisms such as emergency stop functions and protective casings. Operators can confidently use a semi automatic bottle labeler with minimal risk, as built-in features prevent accidents. Durable construction materials withstand long-term industrial use, ensuring the bottle labeling machine remains a reliable asset. Investing in a well-built unit reduces downtime, maximizes productivity, and enhances workplace safety.

Cost-Effectiveness and Return on Investment Analysis

A semi automatic bottle labeling machine offers a high return on investment by reducing labor costs and increasing efficiency. Compared to manual labeling, a semi automatic round bottle labeling machine enables faster production, minimizing bottlenecks and optimizing workflow. The semi automatic bottle labeler requires minimal operational costs, with low energy consumption and affordable maintenance. Businesses investing in a bottle labeling machine experience long-term savings, as reduced waste and improved accuracy lead to lower material costs. With increased output and professional-quality labels, small manufacturers can enhance brand presentation and market competitiveness.

Partnership and Distribution Opportunities

Expanding market reach requires strategic partnerships, and we welcome distributors interested in representing our semi automatic bottle labeling machine. Entrepreneurs looking to supply small factories with a semi automatic round bottle labeling machine will find high demand in industries such as food, beverage, cosmetics, and pharmaceuticals. Partnering with us ensures access to cutting-edge technology, comprehensive training, and marketing support. A semi automatic bottle labeler presents an excellent business opportunity for distributors seeking a profitable venture in the industrial equipment market. Reach out to explore partnership opportunities and expand your product portfolio with a top-tier bottle labeling machine.

FAQ: Frequently Asked Questions

Q1: What types of bottles can this machine label?

A1: Our semi automatic bottle labeling machine handles round bottles made of plastic, glass, or metal. Adjustable settings allow for different diameters.

Q2: How fast can this machine label bottles?

A2: Depending on bottle size and label type, a semi automatic round bottle labeling machine processes 15 to 30 bottles per minute.

Q3: Is training required to operate the machine?

A3: No extensive training is needed. The semi automatic bottle labeler features an intuitive interface, making it easy to use with basic instruction.

Q4: What maintenance is required for long-term use?

A4: Regular cleaning, lubrication, and occasional sensor calibration will keep the bottle labeling machine operating efficiently.

Q5: How can I become a distributor for your labeling machines?

A5: Contact us to discuss distribution opportunities, pricing, and regional availability. We support our partners with training and promotional resources.

Related Products of Semi Automatic Round Bottle Labeling Machine

Flat Surface Labeling Machine

Our flat surface labeling machine delivers exceptional performance for small factories. Engineered with precision, our flat labeling machine redefines productivity on compact production lines.

Transparent Roll Labels

Our high-quality labels are specially designed to meet diverse packaging requirements, making them an excellent match for the Box Corner Labeling Machine, delivering exceptional labeling performance and long-lasting results.

Box Corner Labeling Machine

A Box Corner Labeling Machine is a semi-automatic labeling device designed to apply labels precisely to the corners of packaging boxes. It enhances labeling accuracy, ensures a professional finish, and improves overall packaging efficiency. Compared to manual labeling, which is often slow and inconsistent, this machine offers a streamlined solution for businesses looking to scale their packaging process.