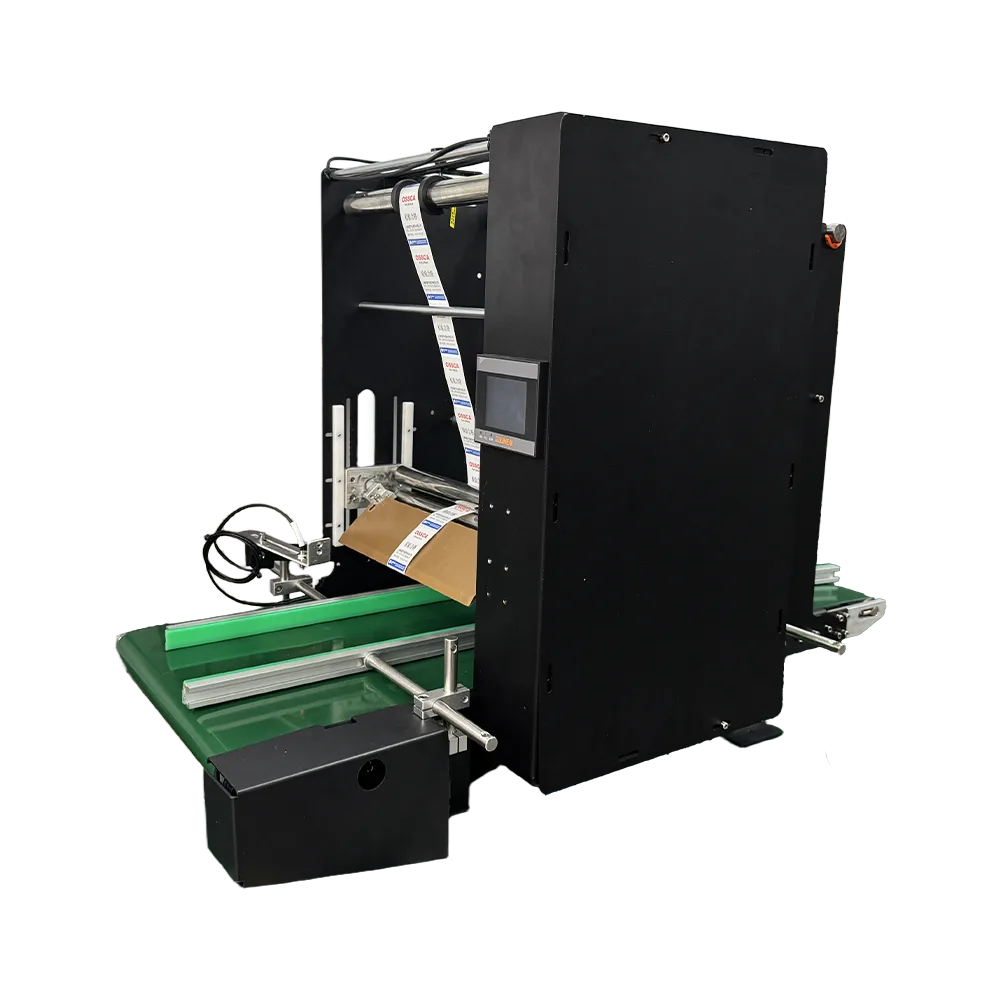

Flat Surface Labeling Machine

Our flat surface labeling machine delivers exceptional performance for small factories. Engineered with precision, our flat labeling machine redefines productivity on compact production lines.

Table of Contents

Introduction to Flat Surface Labeling Machine

This top labeling machine employs advanced mechanisms that enhance accuracy and reduce manual labor. Compact dimensions, measuring roughly one meter by 0.5 meter, ensure suitability for small-scale workshops. Our flat label applicator operates with impressive speed while offering consistent label placement. This semi-automatic flat labeling machine delivers high performance and seamless operation under varied conditions. As a top label applicator, our equipment provides reliable results that empower business growth. Manufacturers enjoy enhanced efficiency with our innovative flat surface labeling machine integrated into production workflows.

Compact Design Advantages for Small Factories

Compact design transforms production workflows in small factories. Our flat labeling machine exhibits an ingeniously efficient form factor that minimizes spatial constraints. Engineered with compact dimensions, each unit occupies minimal floor space. This top labeling machine combines sleek aesthetics and rugged durability in a modest footprint. Its lightweight construction permits easy installation and rapid repositioning when production layouts change. A semi-automatic flat labeling machine integrates innovative electronics with mechanical design in one compact unit. Small businesses experience superior production flows with our flat surface labeling machine integrated into modern assembly lines.

Key Technical Features and Performance Metrics

Innovative engineering defines our key technical features. Our flat surface labeling machine integrates state-of-the-art sensors and precise actuators. Every flat labeling machine boasts advanced digital interfaces that monitor performance. A semi-automatic flat labeling machine supports multiple speed settings and calibration modes. Precision mechanisms grant consistent label placement and minimal deviation under heavy operation. Our top label applicator displays performance metrics, including throughput and error rates. Detailed calibration procedures allow operators to achieve optimal performance and quickly adjust settings during variable production loads.

Efficiency Boost in Small Production Lines

Efficiency boosts production lines in small factories using our innovative equipment. Our flat surface labeling machine accelerates workflows with rapid label application. This flat labeling machine ensures precise placements and shortens production cycles significantly. Small enterprises benefit from a semi-automatic flat labeling machine that minimizes downtime. Streamlined processes arise when operators deploy a flat label applicator in demanding settings. Robust construction guarantees reliability during prolonged high-speed operations on busy floors. Operators appreciate intuitive controls, which foster rapid adjustments under fluctuating production demands.

Customization Options for Diverse Labeling Needs

Customization options empower businesses seeking tailored labeling solutions. Our flat surface labeling machine supports adjustable settings that match varied production requirements. Each flat labeling machine offers modular features that facilitate unique brand specifications. A semi-automatic flat labeling machine includes programmable options for label positioning and speed control. Adjustable rollers, dynamic sensors, and intuitive interfaces meet specific client demands reliably. Our flat label applicator design enables swift changes without extensive downtime, ensuring optimal versatility.

Seamless Integration with Existing Systems

Seamless integration revolutionizes production environments in modern factories. Our flat surface labeling machine effortlessly connects with diverse manufacturing setups. Engineers design every flat labeling machine with plug-and-play compatibility in mind. A semi-automatic flat labeling machine integrates smoothly into existing lines without disruption. System integration features incorporate digital interfaces, real-time monitoring, and simple configuration steps. Every flat label applicator syncs with inventory and production management software seamlessly, ensuring minimal downtime and enhanced efficiency.

User-Friendly Operation and Control Interface

User-friendly operation distinguishes our advanced labeling solutions. Our flat surface labeling machine features an intuitive control panel. A semi-automatic flat labeling machine includes touch screen displays, enhancing user interaction. Our top labeling machine offers clear, concise instructions. Simple navigation buttons and ergonomic designs support effortless operation. Engineers incorporate user-centric features that simplify troubleshooting processes. Operators enjoy a streamlined control system that minimizes complexity while enhancing productivity.

Maintenance, Safety, and Reliability Protocols

Robust maintenance protocols ensure long-lasting performance and safety. Our flat surface labeling machine undergoes routine inspections by skilled technicians. Regular cleaning and precise calibrations maintain optimal functionality. A semi-automatic flat labeling machine features built-in safety sensors that detect anomalies promptly. Preventive maintenance schedules reduce unexpected downtime and extend equipment lifespan. Maintenance procedures include scheduled lubrication, component checks, and software updates performed at regular intervals.

Cost-Effectiveness and ROI Analysis

Cost-effectiveness defines our competitive edge in a challenging market. Our flat surface labeling machine offers impressive returns on investment. Small businesses benefit from rapid payback periods and reduced labor expenses. A semi-automatic flat labeling machine minimizes waste and optimizes throughput efficiently. Investment analyses reveal significant improvements in efficiency and overall profitability. Our flat surface labeling machine achieves competitive operating costs within any small production setting, ensuring tangible value quickly.

FAQ: Frequently Asked Questions

Q1: Which surfaces can your flat surface labeling machine efficiently label?

A1: Our equipment handles smooth flat substrates, including plastics, metals, and glass, with remarkable precision.

Q2: How compact is your flat labeling machine?

A2: Dimensions approximate one meter by 0.5 meter, ensuring seamless integration in limited factory spaces.

Q3: What maintenance does a semi-automatic flat labeling machine require?

A3: Routine cleaning, calibration, and periodic software updates maintain optimal performance while reducing downtime.

Q4: How does your top labeling machine guarantee operational safety?

A4: Built-in safety sensors, sturdy construction, and comprehensive diagnostics deliver secure operation during extended use.

Q5: How can I become an authorized distributor for your machines?

A5: Interested partners can contact our sales department for detailed market support, competitive pricing, and comprehensive training opportunities.

Related Products of Flat Surface Labeling Machine

Semi Automatic Round Bottle Labeling Machine

Efficiency meets precision with a semi automatic bottle labeling machine designed for small-scale factories. A well-built semi automatic round bottle labeling machine enhances productivity, ensuring consistent label application with minimal labor.

Transparent Roll Labels

Our high-quality labels are specially designed to meet diverse packaging requirements, making them an excellent match for the Box Corner Labeling Machine, delivering exceptional labeling performance and long-lasting results.

Box Corner Labeling Machine

A Box Corner Labeling Machine is a semi-automatic labeling device designed to apply labels precisely to the corners of packaging boxes. It enhances labeling accuracy, ensures a professional finish, and improves overall packaging efficiency. Compared to manual labeling, which is often slow and inconsistent, this machine offers a streamlined solution for businesses looking to scale their packaging process.